Project Lead

Project Lead

Research

Product Design

Patent Law

CEO of Voyage Biomedical

CTO of Voyage Biomedical

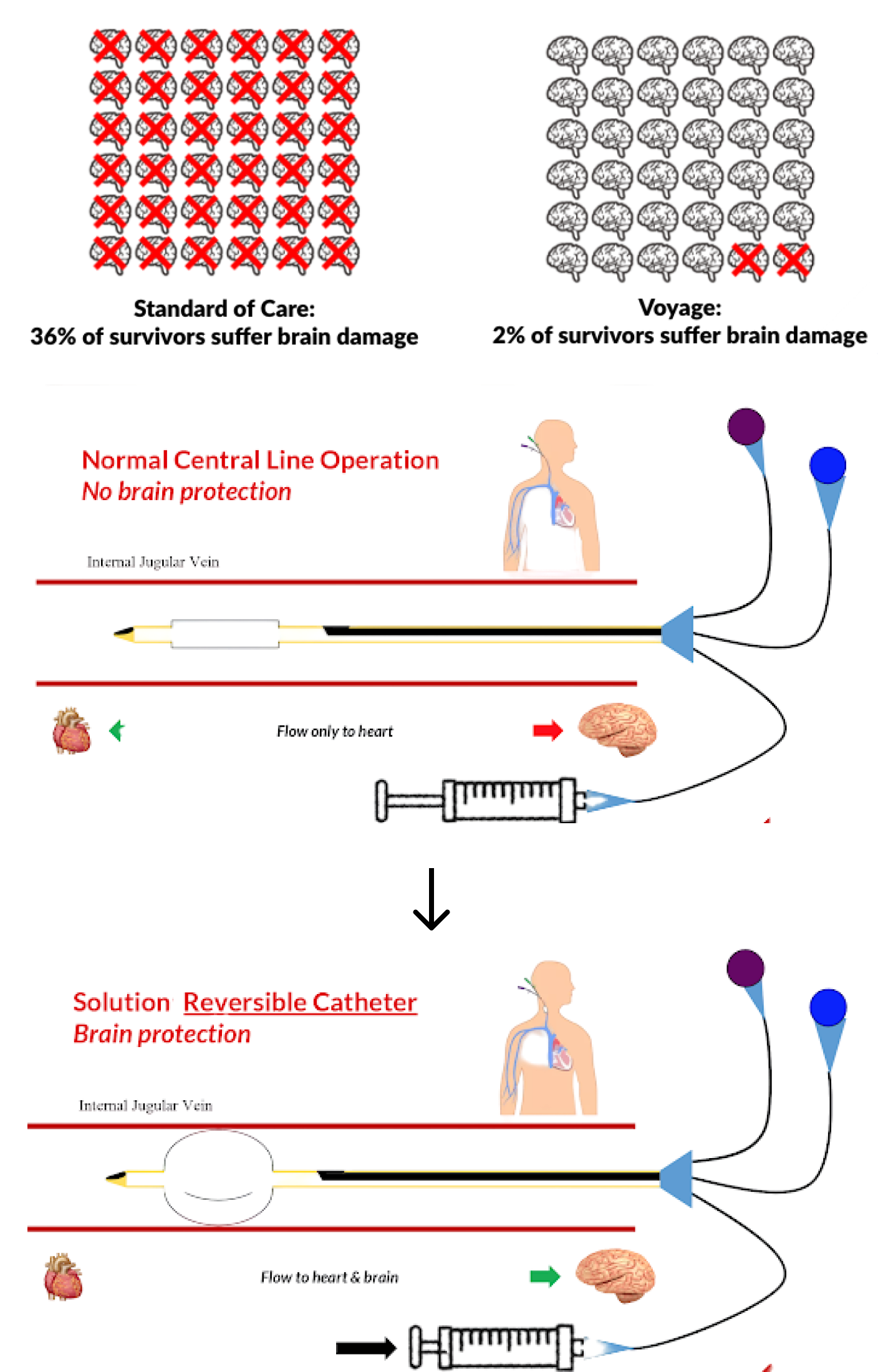

Voyage Biomedical was created to design a central venous catheter capable of traditional catheter function, with the additional ability of emergency brain perfusion technology. We spearheaded multiple initiatives to improve and test their technology.

Voyage Biomedical is a biomedical startup that aims to pioneer life-altering solutions that impact the wellness of patients. Accepted into Y Combinator’s summer cohort after our partnership, Voyage is now part of the National Science Foundation’s I-Corps program. Rob Schulz is a physician and cardiac surgery resident in his fifth year. Justin Olshavsky specializes in mechanical design and robotics, with Master’s degrees in Mechanical Engineering and Translational Medicine.

Each year, over 290,000 ICU patients suffer from in-hospital cardiac arrest. Brain damage occurs in 16,000 of the survivors, negatively impacting their quality of life, creating emotional burden on the survivors’ family members, and equating a total healthcare cost of $2.27 billion per year. To prevent these negative effects, we sought to find the most effective way to cool the brain during cardiac arrest.

who are at risk for and experience in-hospital cardiac arrest

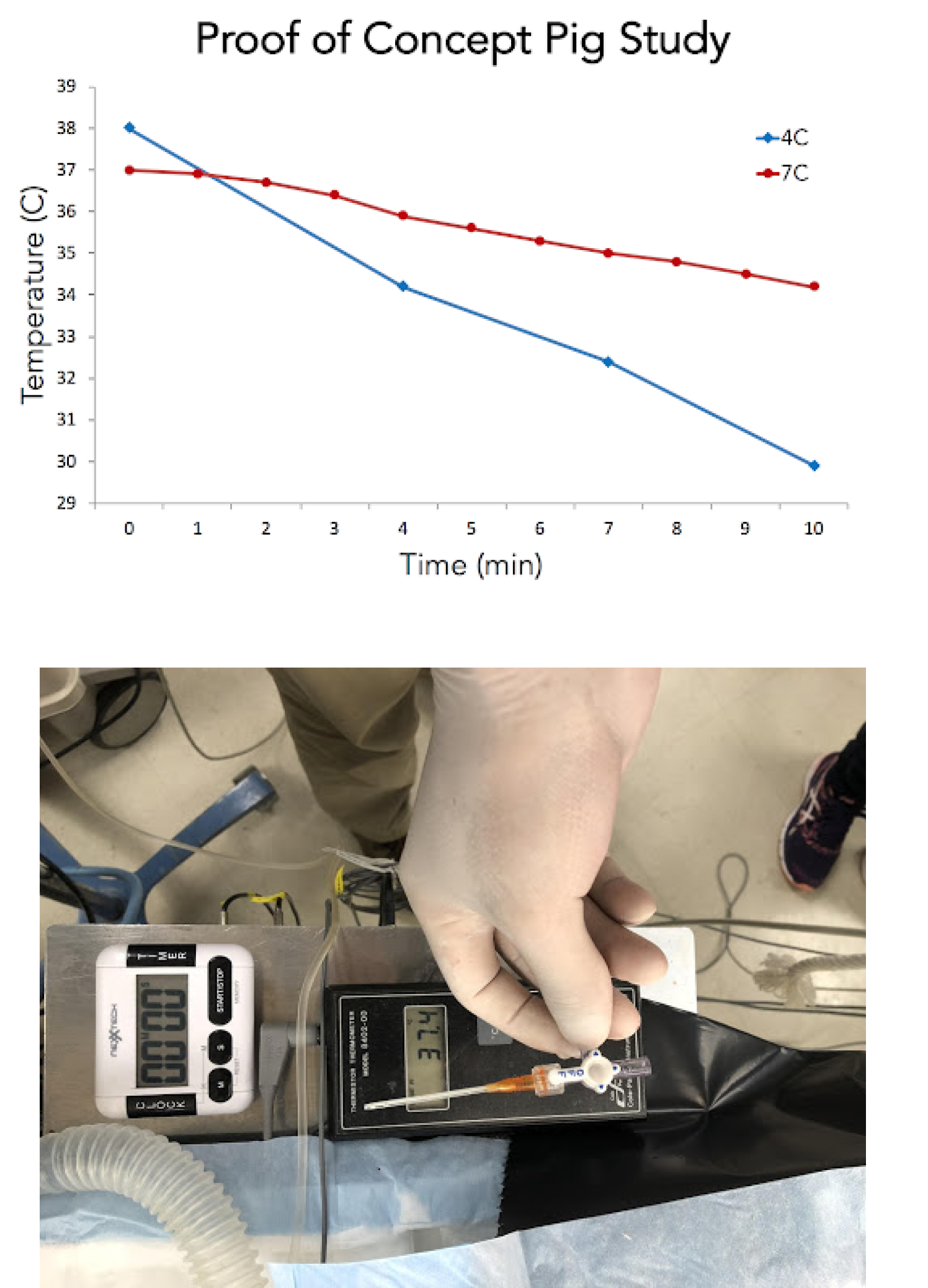

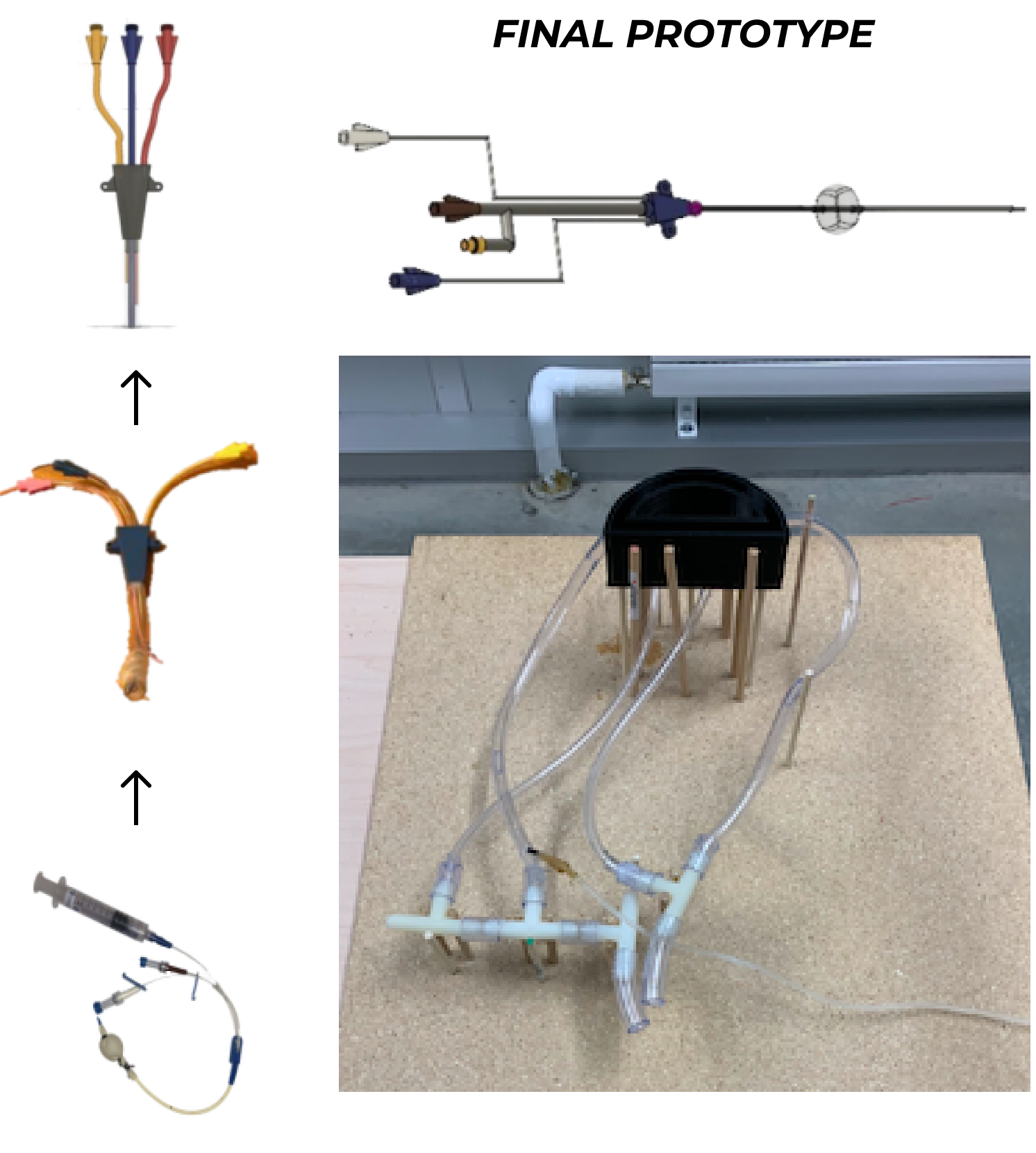

We set out to develop a catheter with a reversible central venous line to achieve the goal of cooling the brain during cardiac arrest. The catheter pumps saline to the brain to cool it down and extend the time the brain has before taking irreversible damage by valuable minutes that allow the procedure to take place. Our process entailed researching and testing prototypes of the catheter.

We began by researching existing floating communities to determine the architectural requirements of a floating residential structure, taking inspiration from similar structures in Ijburg, Netherlands. Combining that inspiration with our own ideas for a functional and comfortable home layout, we sketched designs for two-story homes.

After visualizing a two-dimensional unfolded layout, we created initial prototypes out of cardboard and aluminum foil. Once we tested the efficacy of our 3D designs, we created a higher-fidelity prototype by laser cutting each individual home design from plywood. These structures served as our models for houses.

Our goal was to create a housing layout that reflected a community rather than just individual homes. We tested various

configurations of the laser-cut structures we had created to determine the best possible community arrangement.

For each layout, we gathered user feedback from Bay Area residents about its potential liveability to gain more insight

into how individuals might interact within each community design.

Based on our feedback analysis, we ultimately chose a layout with houses arranged around the edges of the block, with a common area in the center of the arrangement. This formation allows for a more protected and cohesive community feel, with space for a public area such as a community center or park.

After deciding on the layout for the houses, we created a model for the entire system. Our purpose was to create a

higher-fidelity model of what the community would look like and how it would interact with a live body of water.

For our final version, we 3D-printed the houses and block. The landform itself was created out of foam and supported by

an outer layer of plywood. A buoyancy calculator was used ensure dimension. All pieces were coated in waterproof gesso

so that the floating ability of the block could be tested with a secluded body of water that can persist without

eutrophication.